SIERRA Thermal Mass Flow meters

General Description

SIERRA Instruments offers heavy industrial thermal gas flow

sensors for very high flows and challenging measurements. The

rugged, heavy-industrial flow meters feature direct mass flow

measurement; state-of-the-art digital technology; heavy-duty, 316

stainless-steel-wetted materials; and our proprietary Dry-Sensor

technology, which is backed by a lifetime limited warranty.

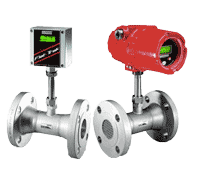

Quadra-Therm™ Model 640i Insertion Mass Flow Meter

The four-sensor QuadraTherm features our no-drift DrySense velocity sensor and works with the iTherm algorithm set to achieve accuracy of +/- 0.75% of reading above 50% of full scale. iTherm is also the "Brain" behind the flowmeter’s capability to change gas (Dial-A-Gas) and pipe size (Dial-A-Pipe) in the field, while also allowing gas updates to the instrument via the internet which connects to the most up to date gases in our proprietary iTherm Gas Library.

- Pressure: 33 bar

- Temp.: -40°C - 200°C

- Flow Range: up to 305sm/s

- Flow-Accuracy: +/- 0.75% of reading +/- 0.5% of full scale

- Temp-Accuracy: +/- 1°C

- Pressure-Accuracy: +/- 1% of full scale

- Repeatability: +/- 0.15% of full scale

- Materials: 316 stainless steel construction

- Input Power:

- 24 VDC, +/- 10%, 1 Amp

- 100 to 240 VAC ( 0.4 Amps RMS at 230 VAC)

- Output Signal:

- Linear 4–20 mA flow, temperature and pressure (optional)

- Alarm ouput (contact SPST/opto relays)

- User definable pulse output for totalized flow

- Digital Communication Options:

- Foundation Fieldbus

- Profibus DP Pending

- MODBUS

- HART

- DeviceNet

- Temperature output

- optional pressure output

- Dial-a-gas technology

- Dial-a-pipe technology (variable pipe diameters)

- Range of process connections (including hot tap)

- Field Validation/Configuration

- Very large installed base

- Removable probe for recalibration and service

- Meters all process gases

Quadra-Therm™ Model 780i in-Line Mass flow meter

The four-sensor QuadraTherm features our no-drift DrySense velocity sensor and works with the iTherm algorithm set to achieve accuracy of +/- 0.5% of reading above 50% of full scale. iTherm is also the "Brain" behind the flowmeter’s capability to change gas (Dial-A-Gas) and pipe size (Dial-A-Pipe) in the field, while also allowing gas updates to the instrument via the internet which connects to the most up to date gases in our proprietary iTherm Gas Library.

- Pressure: 33 bar

- Temp.: -40°C - 200°C

- Flow Range: up to 305sm/s

- Flow-Accuracy: +/- 0.5% of reading +/- 0.5% of full scale

- Temp-Accuracy: +/- 1°C

- Pressure-Accuracy: +/- 1% of full scale

- Repeatability: +/- 0.15% of full scale

- Materials: 316 stainless steel construction

- Input Power:

- 24 VDC, +/- 10%, 1 Amp

- 100 to 240 VAC ( 0.4 Amps RMS at 230 VAC)

- Output Signal:

- Linear 4–20 mA flow, temperature and pressure (optional)

- Alarm ouput (contact SPST/opto relays)

- User definable pulse output for totalized flow

- Digital Communication Options:

- Foundation Fieldbus

- Profibus DP Pending

- MODBUS

- HART

- DeviceNet

- Temperature output

- optional pressure output

- Dial-a-gas technology

- Dial-a-pipe technology (variable pipe diameters)

- Range of process connections (including hot tap)

- Field Validation/Configuration

- Very large installed base

- Removable probe for recalibration and service

- Meters all process gases

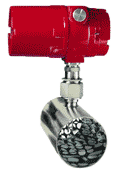

Steel-Mass™ Model 640S Insertion Mass Flow Meter

Accurate and repeatable, this product is a rugged and reliable mass flow measurement workhorse in heavy industrial applications. Product accuracy is ± 1% of reading +0.5% full scale, and the flow range is up to 20,000 sfpm (air) with standard accuracy. It inserts easily into ducts and pipes to monitor total gas mass flow rate and is optimized for greenhouse gas measurement.

- Pressure: 10-70 bar

- Temp.: -40°C - 177°C (High Temperature Option up to 400°C with air)

- Accuracy: +/- 1% of reading +/- 0.5% of full scale

- Repeatability: +/- 0.2% of full scale

- Materials: 316 stainless steel construction

- Input Power:

- 18 - 30 VDC (regulated) max. 625mA

- 100 to 240 VAC, 50/60Hz, max. 15 watts

- Output Signal:

- Linear 0–5 VDC or 0-10 VDC, 1000 ohms minimum load resistance

- Linear 4–20 mA proportional to mass flow rate

- Digital Communication Options:

- Foundation Fieldbus (read only; flow and totalized flow)

- Profibus DP(read only; flow and totalized flow)

- MODBUS RTU (read/write most parameters)

- RS-232 (standard; command set available)

- Range of process connections (including hot tap)

- Field Validation/Configuration

- Very large installed base

- Removable probe for recalibration and service

- Meters all process gases

- 3/4” diameter insertion probe

- Certified greenhouse gas (GHG) air flow meter

Flat-Trak™ Model 780S In-line Mass Flow Meter FC

Like its cousin the Model 640S, the Flat-Trak Model 780S provides repeatable, rugged, and reliable performance. Additionally, the product features Sierra’s flow conditioning elements. Product accuracy is ± 1% of reading +0.5% full scale, and the flow range is up to 20,000 sfpm (air) with standard accuracy. The Model 780S is also optimized for greenhouse gas measurement.

- Pressure: 10-34.5 bar

- Temp.: -40°C - 177°C

- Accuracy: +/- 1% of reading + 0.5% of full scale

- Repeatability: +/- 0.2% of full scale

- Materials: 316L stainless steel construction

- Input Power:

- 18 - 30 VDC (regulated) max. 625mA

- 100 to 240 VAC, 50/60Hz, max. 15 wat

- Output Signal:

- Linear 0–5 VDC or 0-10 VDC, 1000 ohms minimum load resistance

- Linear 4–20 mA proportional to mass flow rate

- 700 ohms maximum resistance power supply dependent

User-selectable: Active non-galvanically separated or Passive

galvanically separated (loop power required

- Digital Communication Options:

- Foundation Fieldbus (read only; flow and totalized flow)

- Profibus DP(read only; flow and totalized flow)

- MODBUS RTU (read/write most parameters)

- RS-232 (standard; command set available

- Range of process connections

- Field Validation/Configuration

- +/ 1% of reading accuracy

- Very large installed base

- Removable probe for recal/service

- In-line flow conditioning

- Meters all process gases

- Certified greenhouse gas (GHG) air flow meter

Ultra High Purity Model 780S UHP In-line Mass Flow Meter FC

This model is the industry choice for gas distribution in ultra-clean processes. This product features 316L electropolished tubing with 7-10 Ra or 20-25 Ra interior finishes.

- Pressure: 10-34.5 bar

- Temp.: -40°C - 177°C

- Accuracy: +/- 1% of reading + 0.5% of full scale

- Repeatability: +/- 0.2% of full scale

- Materials: 316L electropolished tubing

- Input Power:

- 18 - 30 VDC (regulated) max. 625mA

- 100 to 240 VAC, 50/60Hz, max. 15 wat

- Output Signal:

- Linear 0–5 VDC or 0-10 VDC, 1000 ohms minimum load resistance

- Linear 4–20 mA proportional to mass flow rate

- 700 ohms maximum resistance power supply dependent

User-selectable: Active non-galvanically separated or Passive

galvanically separated (loop power required)

- Digital Communication Options:

- Foundation Fieldbus (read only; flow and totalized flow)

- Profibus DP(read only; flow and totalized flow)

- MODBUS RTU (read/write most parameters)

- RS-232 (standard; command set available)

- 316L stainless steel electropolished tubing

- Choice of 7-10 Ra (UHP)

- Pipe sizes from 1/2-inch up to 12-inches

- Range of process connections

- Field Validation/Configuration

- +/ 1% of reading accuracy

- In-line flow conditioning

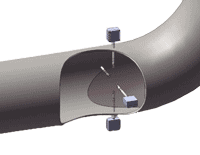

Multi-Trak™ Model 670S Multi-point Flowmeter

Sierra's Multi-Trak™ Model 670S is an advanced state-of-the-art instrument for measuring mass flow rates in very large ducts or stacks that have non-uniform velocity profiles, high turn-down requirements, dirty gas streams, wide temperature ranges and fast velocity and temperature changes.

- Pressure: 10-70 bar

- Temp.: -40°C - 177°C (High Temperature Option up to 400°C with air)

- Accuracy: +/- 1% of reading + 0.5% of full scale

- Repeatability: +/- 0.2% of full scale

- Materials: 316 stainless steel construction

- Input Power: 18 - 30 VDC (regulated), max. 625mA

- Output Signal: Linear 4-20 mA proportional to grand-average flow signal

- The standard Model 670S system consists of up to four sensing points linked via Modbus, one control box with touch-screen HMI and a 4-20mA output module with the associated cables (power, 4-20mA output cable for daisy-chaining all sensing points).

- Innovative and user-friendly HMI offers advances over industry-standard collector boxes and allows users to:

- Average the flow of 4 meters

- Convert flow units

- Set up the density of the gas for mass flow measurement

- Easily configure the individual meters

- Set up alarms

- Unique multiple transmitter approach allows individual points to be removed for service or repair without shutting down the system

- Direct mass flow monitoring eliminates the need for separate temperature and pressure inputs

- Patented Dry-Sense™ technology eliminates sensor drift

- State-of-the-art calibration facility ensures a highly accurate calibration that matches the application

- Low pressure hot taps available

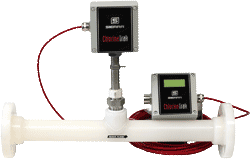

Chlorine-Trak™ Model 760S Chlorine Mass Flow Meter

A special version of the Model 780S, the ChlorineTrak 760S is specifically designed as a cost-effective mass-flow measurement solution for chlorine injection processes found in typical waste-water treatment applications. Product accuracy is +/- 5% of full scale, and the flow range is up to 300 scfm chlorine in a 4” Kynar® flow body.

- Pressure: 8 bar (gas pressure)

- Temp.: -9°C - 32°C (gas temperature)

- Accuracy: +/- 5% of reading

- Repeatability: +/- 0.2% of full scale

- Materials:

- Flow Body: Kynar® polyvinylidene fluoride resin

- Sensor: Hastelloy C probe

- Input Power:

- 18 - 30 VDC (regulated) max. 625mA

- 100 to 240 VAC, 50/60Hz, max. 15 wat

- Output Signal:

- Linear 4–20 mA proportional to mass flow rate

- 700 ohms maximum resistance power supply dependent

User-selectable: Active non-galvanically separated or Passive

galvanically separated (loop power require

Fast-Flo™ Model 620S Insertion Mass Flow Meter

A 200 msec fast time-response microprocessor-based transmitter in a NEMA 4X (IP65) enclosure. Product accuracy is ± 1% of full scale and the flow range is up to 20,000 sfpm (air) with standard accuracy

- Pressure: 8 bar

- Temp.: -40°C - 80°C (Gas)

- Accuracy: +/- 1% of full scale

- Repeatability: +/- 0.2% of full scale

- Materials: 316 stainless steel construction

- Input Power: 18 - 30 VDC (regulated), max. 625mA

- Output Signal:

- 0-5 VDC or 0-10VDC, 1000 ohms minimum load resistance or

Linear 4–20 mA proportional to mass flow rate, - 700 ohms maximum resistance power supply dependent

User-selectable. Active non-galvanically separated or

passive galvanically separated (loop power required)

- 0-5 VDC or 0-10VDC, 1000 ohms minimum load resistance or

- 200 msec time-response

- NEMA 4X (IP65) enclosure

- Field validation & diagnostics

- Field adjustment

- 2 x 12 backlit LCD readout

- 3/8” diameter insertion probe

- Probe lengths up to 24”